What are the functions of collectors froth stabilizers and depressants in froth floatation process?

In froth floatation process, depressant prevants the formation of froth. It is used to separate two sulphide ores by preventing the formation of froth of one sulphide ore and allowing the other to form the froth e.g NaCN, a depresant selectively prevents Zns from coming in froth but allows PbS to come with the froth.

What is the role of stabilizers?

A stabilizer is an electrical device that protects electrical appliances from voltage fluctuations. In the case of refrigerators, voltage fluctuations can damage the compressor and other electrical components, leading to costly repairs or replacement.

What is the frothing agent in froth flotation?

Reason: Mustard oil is used as frother in froth floation process.

What is the role of the frother in froth flotation?

The purpose of the frother is to produce a sizable amount of small air bubbles, thus increasing the surface area of the air introduced into the flotation machine. This increases the number of collisions of coal particles with the bubbles and the chances of the particles being floated to the surface.

What is the role of froth stabilizers in froth floatation process?

The role of the stabilizer in the froth flotation process is explained in the following points: It is used to stabilize the froth such as cresols and aniline. It reduces the cost of mineral processing to the minimum value. It increases the non-wettability of the mineral particles.

What is the role of collectors in the froth floatation process?

Collectors are the floatation reagents used to form a thin hydrophobic layer over the surface of minerals. It increases the floating ability of minerals by increasing the contact angle. Therefore more bubbles with desired minerals adhere to the surface.

What is the main function of a stabilizer?

The main function of a stabilizer is to make the output voltage that feeds the equipment connected to it as much as possible equivalent to the ideal electrical power supply, ensuring that the oscillations in electrical power are offset, and its output maintains a stable value, preventing them from being experienced by …

What is the role of the Stabiliser?

Compared to prime muscle mover muscles such as the biceps/triceps (arms), pecs (chest), and quadriceps (upper thigh), the stabilizers are generally deeper within the body and closer to the joints they stabilize. Their primary function is to provide support and stability to joints during movement.

What is an example of a froth stabilizer?

Common examples of froth stabilizers are cresol and aniline.

What is the role of depressants in froth flotation?

-In froth floatation method, the depressant is used to separate two sulphide ores by preventing the formation of froth by one ore and allow the other ore to be attached with the froth. -Example: For separating two ores ZnS and PbS, NaCN is used as a depressant.

What is froth stability in froth flotation?

Froth stability is a qualitative concept and is known to play an important role in flotation performance. Higher froth stability improves recovery at the expense of grade, and lower froth stability improves selectivity. Recently various techniques have been developed to measure froth stability on an industrial scale.

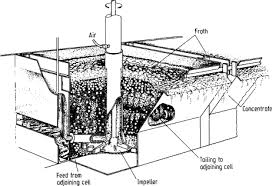

How does froth flotation work?

For example, froth flotation is a technique commonly used in the mining industry. In this technique, particles of interest are physically separated from a liquid phase as a result of differences in the ability of air bubbles to selectively adhere to the surface of the particles, based upon their hydrophobicity.

What is the role of frother on bubble production and Behaviour in flotation?

Compared to water alone, the addition of frother produces a narrower distribution and finer bubble size. An empirical model is presented for bubble size as a function of frother type using a normalized concentration. The model provides a benchmark for assessing operations.

What is the role of activators in froth flotation?

The froth flotation method depends on the flotation reagents, not on the properties of minerals. Ans. An activator is a kind of catalyst that promotes the binding between collector molecules and desired minerals. It helps levitate one mineral in preference to another.

Which oil is used as frother in froth floatation process?

Pine oil enhances non-wettability of the mineral particles. So, it is used as frothier in froth-flotation process.

What is the foaming agent in froth flotation?

In froth floatation process, pine oil is used to produce foam. Q. Generally, for which of the following ores, froth floatation method is used for concentration?

What are the reagents of froth flotation?

Collectors, activators, frothers, modifiers and depressants are the reagents used in froth flotation. A large amount of reagents is used in the process.

What is the role of pH in froth flotation?

pH modifier is important in froth floatation because it promotes anionic or cationic collectors and promotes floatation of gangue at the same time.

What is the role of stabilizer in froth floatation process?

The correct answer is Cresol. Froth stabilizers are substances that help stabilize the froth formed during the froth flotation process. In order to get the froth to be stable, we use froth stabilizers so that the froth can be skimmed off easily. Common examples of froth stabilizers are cresol and aniline.

What is the importance of frother in flotation?

The significance of frothers in the context of mineral flotation is widely recognized, particularly in relation to their impact on bubble size and dispersion, coalescence inhibition, as well as the structure and stability of the froth.

What is the effect of collector in flotation?

Addition of collectors such as #2 fuel oil and kerosene significantly enhances the hydrophobicity of the coal particles without affecting the surfaces of the associated ash-forming minerals. This improves the recovery of the coal, and increases the selectivity between coal particles and mineral matter.

What is the role of a stabiliser?

At its most basic, a stabilizer is any substance that is used to preserve the physical and chemical properties of a material and prevent degradation. At a chemical level, these stabilizers work by inhibiting chemical reactions.

What is the purpose of the stabilizer system?

A stabilizer bar system is part of most vehicle suspension systems. It is designed to reduce body roll and fine tune the suspension as mentioned in the ideal scenario above.

Why are stabilizers used?

Stabilizers are substances that increase stability and thickness by helping foods remain in an emulsion and retain physical characteristics. Ingredients that normally do not mix, such as oil and water, need stabilizers. Many low-fat foods are dependent on stabilizers.

What is the function of stabilizer?

A voltage stabilizer is a device to automatically maintain a constant voltage level. It is an electrical device that is used to provide a stable voltage output to a load at its output terminals irrespective of any variations in the input i.e incoming supply.

What is the use of Stabiliser?

Voltage Stabilizer maintains a constant flow of electric current to the appliances. This enhances their efficiency and helps in smooth running of the appliance. The smooth uninterrupted voltage input helps the gadgets to remain in good condition and thus, enhances the longevity of the appliances.

What is the function of stabilizing agents?

It is used as a thickener in soups, sauces, gravies, shakes, syrups, relishes, and toppings. It is also used as a suspending agent in a number of foods, including dressings, cake mixes, and batter.

What is the role of depressants in froth flotation method?

-In froth floatation method, the depressant is used to separate two sulphide ores by preventing the formation of froth by one ore and allow the other ore to be attached with the froth. -Example: For separating two ores ZnS and PbS, NaCN is used as a depressant.

What is the purpose of depressant in flotation?

Depressants in froth flotation are used to increase the efficiency of the flotation process by selectively inhibiting the interaction of one mineral with the collector, for example, the depression of quartzite to allow for more optimal apatite/collector interaction, thus improving final recovery and grade.

What are the depressing agents in froth flotation?

Generally sodium cyanide and sodium carbonate are used as an depressing agents for forth floatation process. These reagents are used to selectively prevent other metal sulphides from coming to the forth.

What are frothers and collectors in flotation?

A good example of such frother-collectors are amines and amine salts with long (up to 18) carbon chains. Dodecyl amine salts or tallow amine are often used as frother-collectors in silica and other quartz mineral flotation (Hanumantha Rao and Forssberg, 1997, Hedberg, 1970).

Why is froth stability important in mineral flotation?

What is froth flotation?

Why are frothers important in mineral flotation?

How does a froth flotation machine work?

Let’s dive into the world of froth stabilizers and understand how they make froth flotation work its magic.

What are Froth Stabilizers?

Froth stabilizers, sometimes called frothers, are essential chemicals in froth flotation. They are added to the slurry (the mixture of ground ore and water) to create a stable froth. Imagine it like this: the froth is like a collection of tiny bubbles, and froth stabilizers help these bubbles stick together and form a nice, stable layer.

Why are Froth Stabilizers Important?

Think of froth stabilizers as the glue that holds the froth together. They are important because:

They enhance froth stability: A stable froth allows the valuable minerals to be collected efficiently. The froth needs to be stable enough to hold the minerals long enough to be skimmed off, but not so stable that it becomes difficult to break down.

They influence froth characteristics: Froth stabilizers can also influence the froth characteristics, such as its density, bubble size, and stability, which can affect the overall efficiency of the flotation process.

They impact the recovery of minerals: The selection of the right froth stabilizer is critical to ensuring optimal recovery of the desired mineral.

How Froth Stabilizers Work

Froth stabilizers work by reducing the surface tension of the water in the slurry. You know how water molecules like to stick together? Froth stabilizers weaken that attraction, making it easier for air bubbles to form and stay stable.

When air is introduced into the slurry, froth stabilizers help to create a stable froth by:

Reducing the surface tension of the water: This allows for the formation of small, stable bubbles.

Forming a thin, hydrophobic layer around the bubbles: This layer prevents the bubbles from collapsing and helps them stick together.

The result? A robust froth that effectively carries the desired mineral particles to the surface.

Types of Froth Stabilizers

There are a bunch of different froth stabilizers available, each with its own set of characteristics and applications. Some common types include:

Alcohols: These are commonly used froth stabilizers. They are relatively inexpensive and effective in many applications.

Amines: These are often used in sulfide ore flotation, especially for copper, lead, and zinc.

Polyglycols: These are often used for non-sulfide ores, like phosphate and iron.

MIBC (methyl isobutyl carbinol): This is a very popular frother, especially in copper flotation.

Choosing the Right Froth Stabilizer

Picking the right froth stabilizer for a specific flotation process is critical. The choice depends on factors such as:

The type of mineral being floated: Different minerals require different froth stabilizers for optimal performance.

The characteristics of the ore: For example, the size of the mineral particles, the amount of gangue, and the presence of other minerals can influence the choice of froth stabilizer.

The flotation conditions: Factors such as the pH of the slurry, the temperature, and the flow rate can also impact the performance of froth stabilizers.

Optimizing Froth Stability

To get the most out of your froth stabilizers, you can tweak some parameters.

Dosage: The amount of froth stabilizer added to the slurry can significantly impact the stability of the froth. Too little, and the froth won’t be stable enough. Too much, and it could become too stable, making it hard to skim off.

Type of Frother: As mentioned, there are different types of froth stabilizers, each with unique properties.

pH: The pH of the slurry can influence the effectiveness of froth stabilizers.

Temperature: Temperature can also affect the performance of froth stabilizers.

FAQs

Q: What is the difference between a collector and a frother?

A: Collectors are used to make the mineral particles hydrophobic (water-repelling), which allows them to attach to air bubbles. Frothers help stabilize the froth and ensure the bubbles remain intact long enough to carry the mineral particles to the surface.

Q: How can I tell if I am using the right frother?

A: Look for a froth that is stable, with bubbles of an appropriate size, and that efficiently carries the desired mineral particles to the surface. If you see an unstable froth, or if the recovery of the desired mineral is low, you may need to adjust the type or dosage of your froth stabilizer.

Q: What happens if I don’t use a frother?

A: Without a froth stabilizer, the bubbles in the slurry will be unstable and will quickly collapse. This will result in poor mineral recovery, as the mineral particles won’t be effectively carried to the surface.

Q: Can I use a frother for every type of mineral?

A: No. Different froth stabilizers are effective for different minerals. It’s important to choose the right froth stabilizer based on the specific mineral you are trying to float.

Q: What are the environmental concerns related to froth stabilizers?

A: Some froth stabilizers can be toxic to aquatic life. It’s important to choose environmentally friendly froth stabilizers and to use them responsibly.

Q: Can I reuse the frother?

A: It’s not recommended to reuse frothers as their effectiveness can decrease with time. The best practice is to use fresh frothers for each flotation cycle.

Q: What are some ways to improve froth stability in a flotation process?

A: You can improve froth stability by:

Choosing the right frother: Different types of frothers have different levels of stability.

Adjusting the dosage: Too much or too little frother can negatively impact froth stability.

Optimizing the pH: The pH of the slurry can affect the effectiveness of frothers.

Controlling the temperature: Temperature can also influence the stability of the froth.

I hope this has shed light on the importance of froth stabilizers in the froth flotation process. As you can see, these chemicals are crucial for maximizing mineral recovery and ensuring efficient operation.

Keep in mind, the right choice and optimization of froth stabilizers can make a world of difference in the success of your flotation process.

See more here: What Is The Role Of Stabilizers? | Froth Stabilizers In Froth Floatation Process

Froth Flotation Process – Detailed Explanation with Diagrams and

Froth flotation is an important concentration process that can be used to selectively separate hydrophobic materials from hydrophilic waste gangue. In a more simple context, froth flotation is one of the most popular operational processes for mineral BYJU’S

Frothers in flotation: A review of performance and function in the …

The significance of frothers in the context of mineral flotation is widely recognized, particularly in relation to their impact on bubble size and dispersion, ScienceDirect

1 Froth Flotation – Fundamental Principles

Froth flotation is a highly versatile method for physically separating particles based on differences in the ability of air bubbles to selectively adhere to specific mineral surfaces mtu.edu

The significance of froth stability in mineral flotation — A review

The importance of froth stability in mineral flotation was reviewed. Froth stability determines mineral grade and recovery in flotation operations. Froth stability is ScienceDirect

Fundamentals of froth flotation | ChemTexts – Springer

Froth flotation is a physicochemical separation process in which a mixture of fine mineral particles is mixed with water in a large tank (cell), and a swarm of small Springer

Bubble and Froth Stabilizing Agents in Froth Flotation

In flotation, bubbles and froths are transiently stable by the use of a frothing agent or the presence of inorganic electrolytes in the process water. This Taylor & Francis Online

metallurgy – Froth floatation process – Use of stabilizers in froth …

How exactly do the stabilizers affect the process of Froth floatation method? I mean how do they stabilize the froth in the process? Chemistry Stack Exchange

A review of froth flotation control – ScienceDirect

The Froth Stability Column is an alternative measure of froth stability comprising a non-overflowing column in which the froth rises unhindered. The rate of ScienceDirect

Froth flotation process and its application – Wiley Online Library

The paper is about the froth flotation process and its application. It is a metallurgical process for the extraction of metals in a pure state from their ores: Wiley Online Library

Froth flotation – Wikipedia

Froth flotation is a process for separating minerals from gangue by exploiting differences in their hydrophobicity. Hydrophobicity differences between valuable minerals and waste Wikipedia

See more new information: curtislovellmusic.com

The Flotation Process | Sepro Labs

Animation Of Froth Flotation Process Created For Rio Tinto Innovation By Aarons Cgi

Froth Floatation Process – Ore Dressing

Froth Flotation

The Froth Flotation Process And Its Bubbles

Froth Floatation Process

Froth Floatation Process

Froth Flotation

Link to this article: froth stabilizers in froth floatation process.

See more articles in the same category here: https://curtislovellmusic.com/category/what/